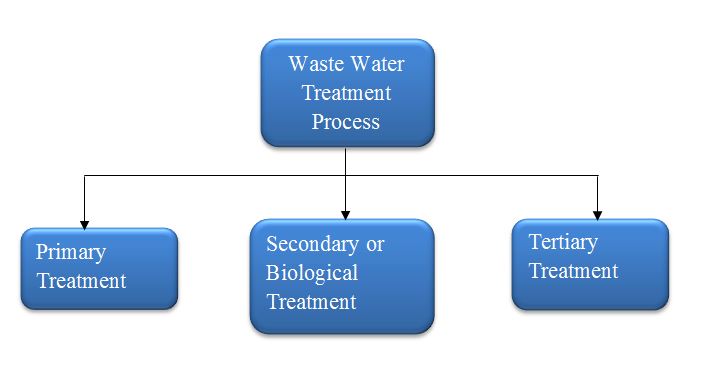

The objective of primary treatment is the removal of settleable organic and inorganic solids by sedimentation, and the removal of materials that will float (scum) by skimming. Approximately 25 to 50% of the incoming biochemical oxygen demand (BOD5), 50 to 70% of the total suspended solids (SS), and 65% of the oil and grease are removed during primary treatment. Some organic nitrogen, organic phosphorus, and heavy metals associated with solids are also removed during primary sedimentation but colloidal and dissolved constituents are not affected. The effluent from primary sedimentation units is referred to as primary effluent.

Biological treatment is the main part of the treatment process to reduce all the parameters by using activated sludge process. Our product (BIOZYME) plays a vital role in the secondary treatment system. Secondary systems produce excess biomass that is biodegradable.Secondary sludges are usually combined with primary sludge for further treatment by anaerobic digestion. The results are gaseous end products, mainly methane and CO2, liquids and inert solids. The effluent from primary treatment plant is sent to secondary treatment plant for further treatment. Secondary treatment is carried out by changing the character of organic matter and thus converting it into stable forms mainly by two methods such as filtration and activated sludge process.In the aeration tank, microorganisms consume the dissolvedorganic pollutants as food and convert organic materials in wastewater to

microbial biomass and CO2 by using O2 provided in the air compressor. The organic nitrogen is converted to ammonium ion or nitrate.Organic phosphorus is converted to orthophosphate. The aerobic microorganisms in the tank grow and multiply, forming an active suspension of biological solids called activated sludge. The combination of the activated sludge and wastewater in the aeration tank is called the mixed liquor.

Basic calculation in aeration tank for biological process. Mixed Liquid Suspended Solids MLSS The suspended solids in the mixed liquid consist mostly of living microorganisms, the suspended solids concentration is used as a measure of the amount of microorganisms in the tank. The F/M ratio The food to microorganism (F/M) ratio is one of the significant design and operational parameters of activated sludge systems. A balance between substrate consumption and biomass generation helps in achieving system equilibrium. The F/M ratio is responsible for the decomposition of organic matter

Biological oxygen demand(BOD) Amount of dissolved oxygen consumed by microorganisms to decompose organic matter in polluted water.

Chemical oxygen demand (COD) Amount of chemically oxidizable materials present in the wastewater

Sludge recycling The MLSS concentration in the aeration tank is controlled by the sludge recirculation rate and the sludge settleability and thickening in the secondary clarifier.

Aerobic microbes require oxygen and organic nutrients to work and grow. Nutrients are provided by the organic material in wastewater and oxygen is usually delivered by pumping air into the treatment tank. The end products of aerobic digestion are energy, carbon dioxide and metabolized solids that settle out. The nutrients and oxygen cause aerobic microbes to multiply and their increased number speeds up the digestion process.

Organic-N + Microorganisms → NH3/ NH4+

Biological treatment in the aerobic process in which the pollutants in the waste water(organic matters) are stabilized by microorganisms in the presence of molecular oxygen.

Biozyme Liquid+ Biozyme Powder = New cell + Biomass growth

More Efficient process to degrade organic pollutants

Fast process to handle large volume of wastewater

The purpose of tertiary treatment is to provide a final treatment stage to raise the effluent quality before it is discharged to the receiving environment such as sea, river, lake, ground, etc., or to raise the treated water quality to such a level to make it suitable for intended reuse. This step removes different types of pollutants such as organic matter, SS, nutrients, pathogens, and heavy metals that secondary treatment is not able to remove. Wastewater effluent becomes even cleaner in this treatment process through the use of stronger and more advanced treatment systems. It includes sedimentation, coagulations, membrane processes, filtration, ion exchange, activated carbon adsorption, electro dialysis, nitrification and di-nitrification, etc.